Post Activation

After activation, the activated carbon to be sizing and sorting before goes in to packing by using following machine.

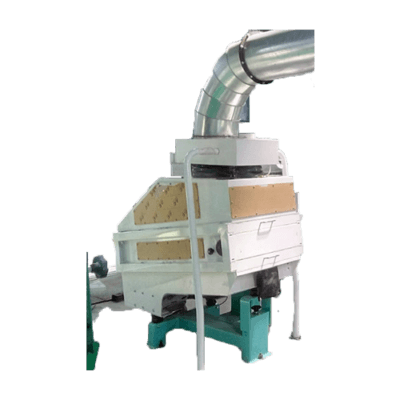

Destoner

A destoner is a machine that removes stones and clods from soil ridges and moves them to the furrow so that the ridges are free from stones. They remove stone using a series of webs (between two and five webs). The stones stay on the web. Destoner is a machine used to remove the stone from the activated carbon. The stones are formed while activation process.

Roll-mill crusher

Roll crushers apply shear or compression to the material that is going to be reduced in size. This action occurs between two hardened surfaces. The speed and diameter of the rolls, the desired capacity, and the feed and product size distribution are all critical in the proper sizing and operation of this type of machine. The roll speed must be sufficient to prevent stalling, but not so fast that the charcoal is violently thrown out of the mill. Roll-mill crusher contains of two rollers that can brake/crush the carbon to the required size. Double-roll crushers are able to crush more finely than single-roll crushers.

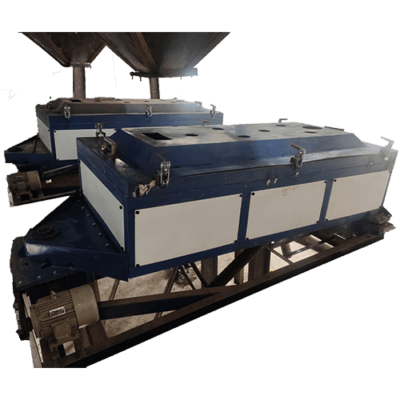

Multi-screener

Multi-screener is the practice of taking granulated ore material and separating it into multiple grades by particle size. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling. A method of separating solid particles according to size alone is called screening. Multi Screener separates a flow of material into grades, these grades are then either further processed to an intermediary product or a finished product. In this we can sort the activated carbon required size for packing.

Wet scrubber

The Wet Scrubber System is an essential air pollution control unit used in activated carbon plants to effectively remove dust, fumes, acid gases, and soluble contaminants from exhaust air streams. It operates by bringing contaminated process gases into direct contact with a scrubbing liquid—typically water allowing pollutants to be absorbed, neutralized, or captured before clean air is released to the atmosphere.

In activated carbon manufacturing, wet scrubbers are commonly installed at high-emission points such as activation kilns, furnaces, and material handling sections. The system efficiently controls particulate matter, volatile compounds, and acidic gases generated during thermal activation and processing operations.

Structure work

Activated Carbon Plant – 2-Stage Structural platform

Stage 1: Machine Support Structure

Robust steel structure designed to support the primary activated carbon processing machine, ensuring stability, safety, and smooth continuous operation. Includes maintenance platforms, access ladders, and safety railings.

Stage 2: Overhead Storage with Rope Hoist

Elevated storage system installed above the Stage 1 machine, equipped with a rope hoist for easy material lifting. Enables gravity feeding to the machine, reduces manual handling, and optimizes plant space.

Key Benefits:

✔ Compact plant layout

✔ Efficient material handling

✔ Safe and durable construction

✔ Low maintenance operation