Activation

In this we can convert the charcoal in to activated carbon by using rotary kiln.

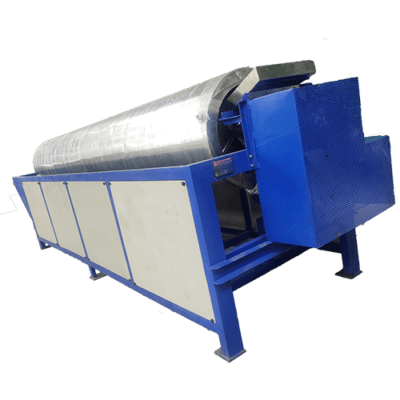

Rotary kiln

The kiln is a cylindrical vessel, which is rotated slowly about its longitudinal axis. The process feedstock is fed into one end of the cylinder. As the kiln rotates, material gradually moves, and may undergo a certain amount of stirring and mixing. The diesel burner is attached in the feeding end for burning purpose. Steam passes along the kiln, for activation. The steam generated in an external boiler. Approximate kiln temperature while the process should be 600°C to 1500°C.

The following single kiln capacities that we have manufacture,

• 1 MT to 1.5MT

• 3MT to 3.5MT

• 5MT to 6MT (Jumbo kiln)

Rotary cooler

Cooling conveyor is also called as indirect rotary coolers. Indirect rotary coolers rely on heat transfer through the drum shell to cool material, utilizing cool water bathed over the drum as it rotates in order to cool the drum shell and subsequently the material within. Indirect rotary coolers can be designed as part of a recycle circuit, where warm water coming off the drum is run through a heat exchanger to cool it and send it back to the beginning of the process. They can also be integrated into existing systems.